- Introduction

- Products

- Technology & R&D

- Contact Us

비쥬얼

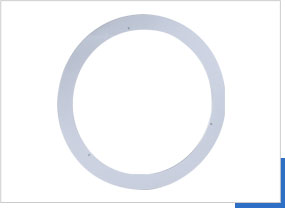

Si (Silicon)

Specification

| Product Name | Silicon Ring |

|---|---|

| Material | Single Crystal Silicon |

Multi Crystal Silicon |

|

| Purity(%) | Single Crystal Silicon ( 8N 99.999999% ) |

Multi Crystal Silicon ( 5N 99.999%) |

|

| Applications | Dry etcher process |

| Out Dia | 520mm ( max ) |

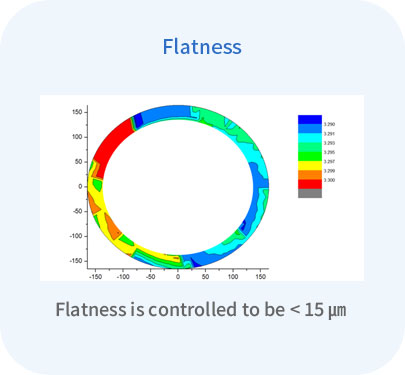

| Thickness (Flatness) | 1~70mm ( <15㎛ ) |

| Res. ( Ω.㎝ ) | Low: < 0.02 Middle : 1~5 High 60~90 |

| Surface Condition | Polishing |

Lapping |

|

Grinding |

|

| Quality ( Visual ) | Chipping |

Scratch |

|

Crack |

|

Stain Free |

|

| Quality ( Cleaning Process ) | 100 ppb or less per element ( Na, Mg, Al, K, Ca, Cr, Fe, Ni, Cu, Zn, and Y ) |

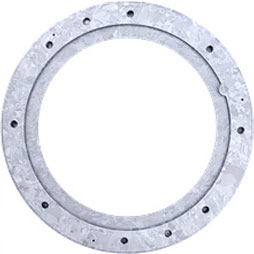

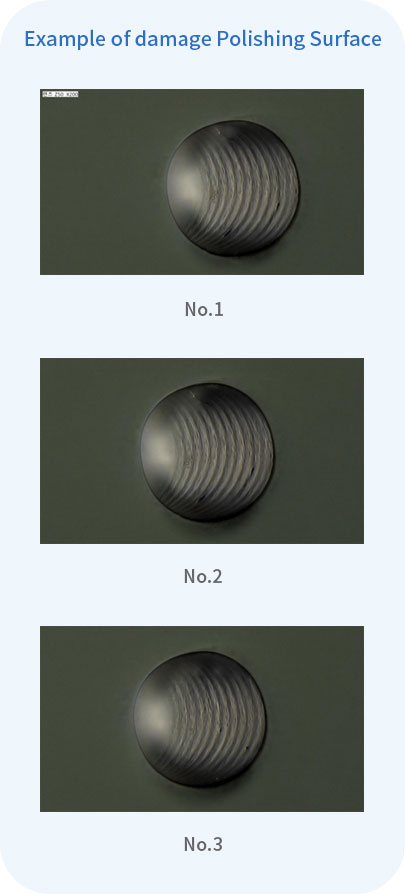

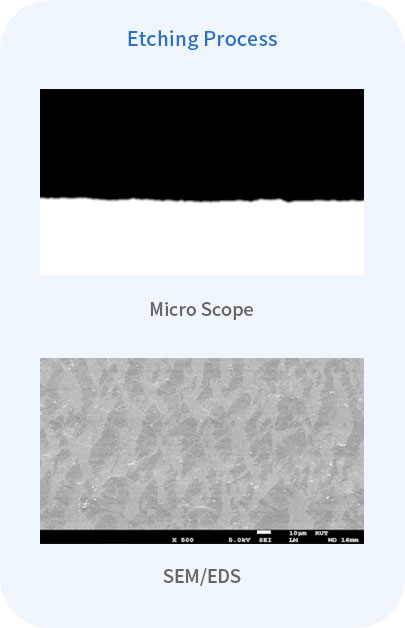

Surface Quality

-

Any damage generated inside holes is removed through an appropriate processing method and proper etching.

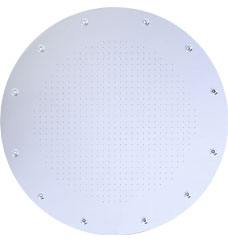

Product Image

Specification

| Product Name | Silicon SHOWER HEAD |

|---|---|

| Material | Single Crystal Silicon |

| 순도(%) | Single Crystal Silicon ( 8N 99.999999% ) |

| Applications | Dry etcher process |

| Out Dia | 440mm ( max ) |

| Thickness (Flatness) | 1 ~ 15mm ( <15㎛ ) |

| Res. ( Ω.㎝ ) | Low: < 0.02 Middle : 1~5 High 60~90 |

| Gas Hole | Diameter 0.3~0.7mm |

Roundness < 0.05mm |

|

Concentricity < 0.05mm |

|

Δ XY-Position < 0.05mm |

|

| Surface Condition | Polishing |

Lapping |

|

Grinding |

|

| Quality ( Visual ) | Chipping |

Scratch |

|

Crack |

|

Stain Free |

|

| Quality ( Cleaning Process ) | 100 ppb or less per element (Na, Mg, Al, K, Ca, Cr, Fe, Ni, Cu, Zn, and Y) |

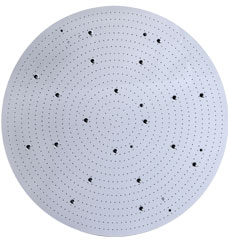

Gas Hole Quality ( Micro Scope )

The quality inside holes is guaranteed through the use ofan appropriate processing method.

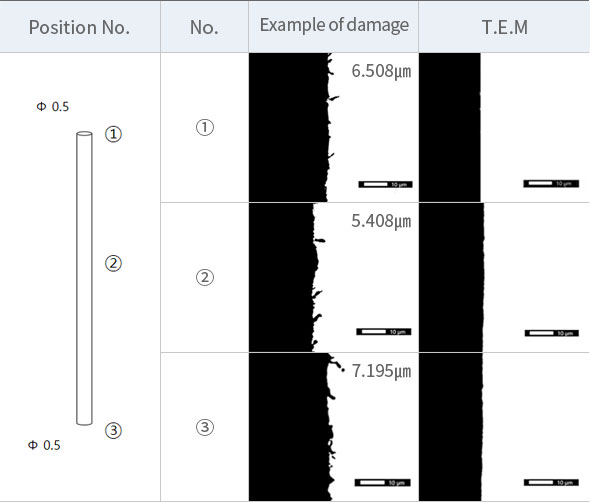

Gas Hole Quality (Damage of Depth)

Any damage generated inside holes is removed through an appropriate processing method and proper etching.